Simplify Process Failure Mode Effects Analysis (PFMEA) with 360 CORE

Manufacturing quality document and report generation, collaboration and management

for FAI, PPAP, AS9100, AS9102, AS13100, IATF 16949 and ISO 13485 standards

Don’t Let Quality Documents Manage You, You Can Manage Them

The revolutionary manufacturing quality document solution, High QA PQP (Production Quality Planning), offers improved document efficiency and simplified communication.

PQP transforms the handling of quality documents by advancing the creation of quality reports and supplier and production facility communication.

Produce quality documents for the automotive (IATF 16949), medical (ISO 13485), aerospace (AS9100, AS13100), and other industry standards, as well as satisfy the documentation requirements for FAI, APQP, and PPAP processes.

WATCH VIDEO – High QA PQP

Access Your Quality Documents - Anytime, Any Place

Electronic documents can perform better than paper documents.

Cut down on expenses and limitations brought on by filing cabinets and paper records. Implement a paperless quality procedure that enables anytime, anywhere access to digital records kept in a central database.

Embrace improved customer engagement and cooperation, transform processes, cut waste, and unleash efficiencies with High QA PQP, the cutting-edge manufacturing quality record system.

- Save up to 70%

- Enhance collaboration

- Boost efficiency

- Facilitate compliance

- Meet expectations

Bring Order to Chaos

Each customer wants a certain set of reports done in a certain way. With High QA PQP, templates and workflows are established for each individual customer.

With all the documents and reports stored in one central database, there is no need to remember and recall which documents are needed for each customer.

Dynamic Documents

High QA central database quality papers are “alive documents.” Data from the database is automatically used to fill up editable fields.

Eliminate Paper Documents

Everyone can use the same information from the same source thanks to digital documents and reports. It lowers the cost of printing and storing paper documents while guaranteeing uniformity.

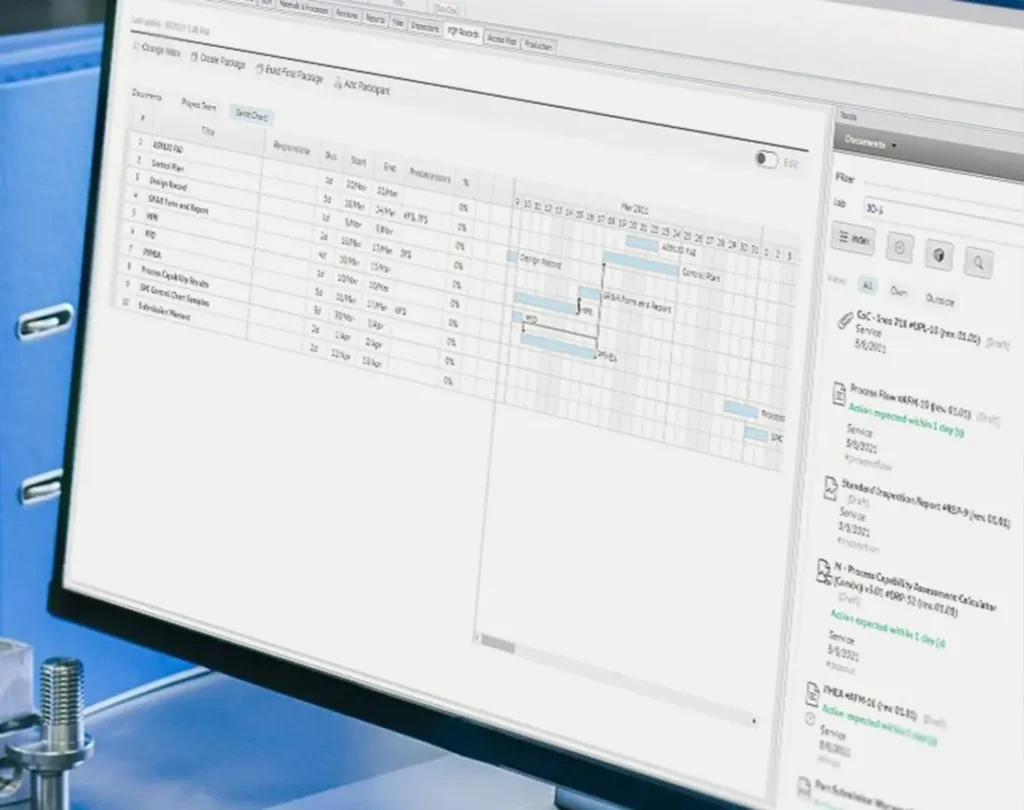

Process Status

Track the status of submission packages, identify bottlenecks, and keep an eye on document progress. Recognize when a paper is finished, behind schedule, or on track. Use Gantt charts and real-time updates to increase efficiency.

Accountability

User responsibility governs and defines all permissions. It is easy to figure out who did what, when, and with approval.

Traceability

No more searching filing cabinets or reams of paper to check if a signature was received. Documents are kept in a central database after being authorized and digitally signed.

Consistency

Make sure that all jobs and clients have the same forms, procedures, and paperwork. Select from the standard templates that are offered or alter them to suit your needs and tastes.

One-Click Submission Package

Give up spending time manually adhering to every component of the Production Part Approval Process (PPAP) in various systems including Microsoft Excel. A single piece of software called High QA PQP makes it easier and more efficient to create, manage, and publish your documents. It includes:

- Ballooned Drawings

- Control Plans

- First Article Inspections (FAI)

- Inspection Plans

- Process Failure Mode Effects Analysis (PFMEA)

- Process Flow (PFlow) Diagrams

- Non-Conformance Report (NCR)

- Statistical Process Control (SPC)

- Gage Management

- Material Certificates

- Part Submission Warrant (PSW)

How Do You Manage Your Manufacturing Quality Documents?

The OLD Way

The internal manufacturing quality process is getting harder and harder to manage. When components are outsourced to a supply chain, the complexity rises with:

- Intensive labor and time to create each new quality project

- Multiple Excel spreadsheets with multiple columns, rows and tabs

- Delays from paper-based communications

- Errors from cutting and pasting critical data from multiple locations

- Variety of methods to control updates, revision control and engineering changes

- Lack of traceability by using paper-based spreadsheets, forms and documents

- Increased risk for material loss, rejected parts and delivery delays

- Missing documents, higher costs and lower part quality

The NEW Way

A potent manufacturing Quality Management System (QMS) for meeting APQP and PPAP process requirements is High QA Production Quality Planning (High QA PQP). It does this by:

- Customized library of templates and forms

- Secure collaboration and communication

- Traceability and accountability for the entire quality process

- Streamlined PPAP process and other quality requirements using 2D drawings or 3D models.

- Compliance to AS9100, AS13100, IATF 16949, ISO 13485 and other quality standards and regulations in aerospace, automotive, medical, energy and other manufacturing industries

- An automated, paperless, database-driven solution that doesn’t rely on Microsoft Excel

Essential Productivity Tools and Features

Centralized database for documents and forms

Adaptable project management templates

Comprehensive automated forms

Secure user access control

Standards-driven production processes

Supplier performance evaluation

Electronic signature confirmations

Powerful revision control management

Flexible configurations and business workflows

High QA 360 Exchange Server for remote and in-network collaboratio

Streamlined practices for compliance with manufacturing quality standards

Customizable library of templates for each buyer and OEM

for All Your Quality and Manufacturing Needs

Powerful Project Management for All Your Quality and Manufacturing Needs Uniting People, Projects and Processes for Unparalleled Manufacturing Quality

Product submission packages are created, monitored, signed, and saved in a completely new way thanks to High QA PQP.

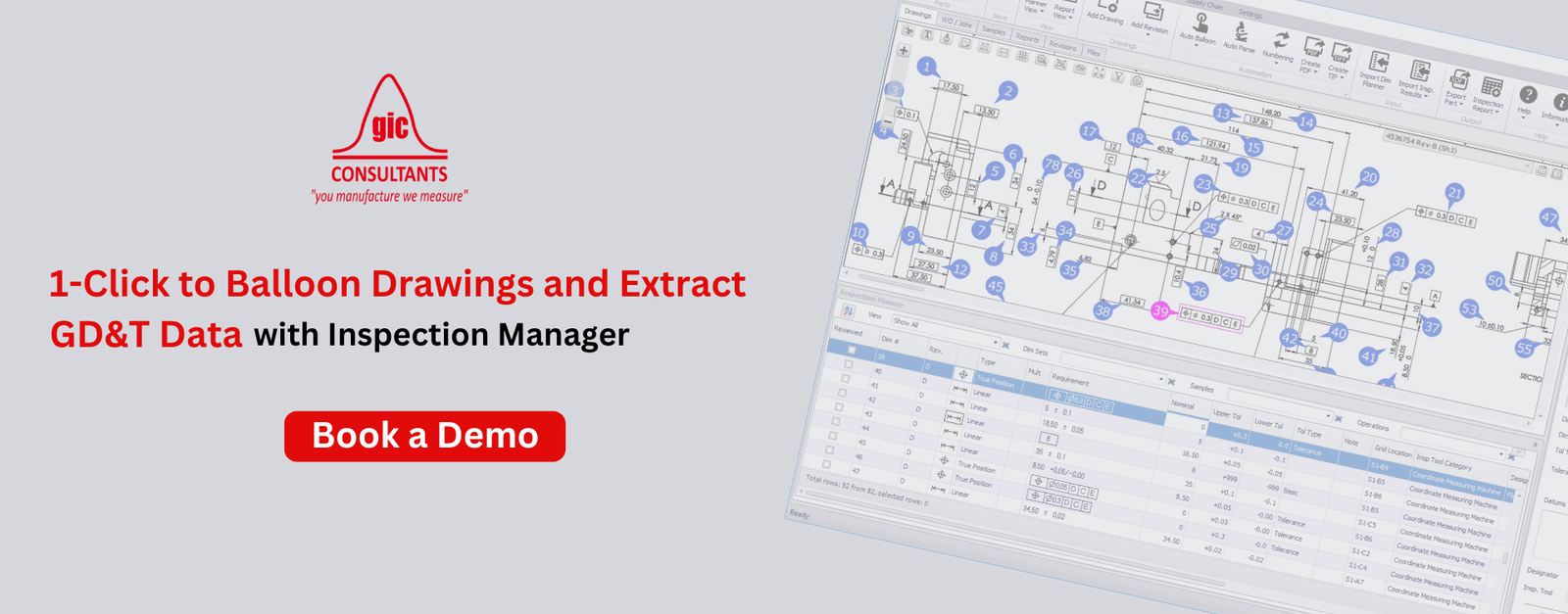

Print ballooning, inspection plan composition, gage management, data collection, NCR tracking, statistical analysis (SPC), and FAIs are all combined into a single software solution that allows you to generate your PFMEA, Control Plan, Process Flow Diagram (PFlow), Part Submission Warrant (PSW), SPC Control Chart, and Gage R&R documents automatically and seamlessly with just one click.

Instead of just maintaining papers, High QA offers a novel and straightforward method for producing comprehensive submission packages for AS13100, ISO13485, or any other industry standard. Let your data do the heavy lifting.

- Highly configurable workflows

- Synchronized data

- Centralized database

- Modern user access control

- Proactive at-risk notifications

- Consistent forms, workflows and documentation

- Centralized database

- Powerful tools for planning requirements, document management and reporting

- Paperless environment

Align and Unify Suppliers and Buyers

High QA PQP enables cross-functional teams to seamlessly and securely collaborate and communicate on manufacturing documents and processes. It also accelerates the time-to-ship parts and reduces scrap by:

- Correctly extracting GD&T and quality requirements

- Providing automation tools to assign measurement techniques, sampling rates, operations, and a host of other configurable settings

- Normalizing and collaborating on standardized forms, workflows and reports (AIAG and ISO standard templates)

- Providing Gage R&R info to verify the inspection tools meet requirements

- Analyzing measurement data to display capability information (Cp, Cpk, Pp, Ppk, etc.) on the shop floor and engineering

- Providing tools to comply with AS13100, AS9100, ISO 9001, IATF 16949, ISO 13485 and other industry standards and regulations

- Capturing traceability of print revisions, engineering changes, approvals, and acceptance of parts