Simplify Process Failure Mode Effects Analysis (PFMEA) with 360 CORE

Generate Consistent, Standardized and Synchronized PFMEA Documents

Utilize pre-formatted and editable templates to save time.

Remove the need for repetitive data entering by automatically generating data across sheets.

Processes for authorization, accountability, and traceability that are entirely digital

Descriptions of failure modes that are consistent throughout all submissions, papers, and supplier submissions.

Sort possible failure scenarios according to frequency, severity, and detection.

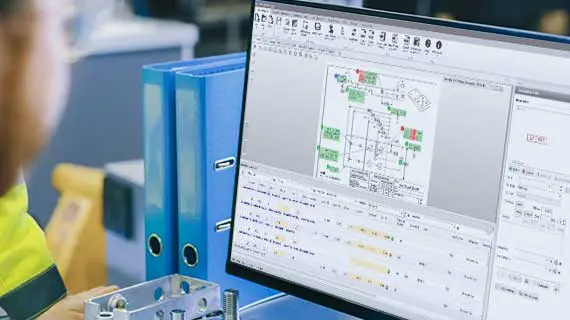

Graphics and visual diagrams that make industrial processes simple to grasps

Learn how you can streamline and optimize your PFMEA

PFMEA As It Should Be!

Easy. Effective. Efficient

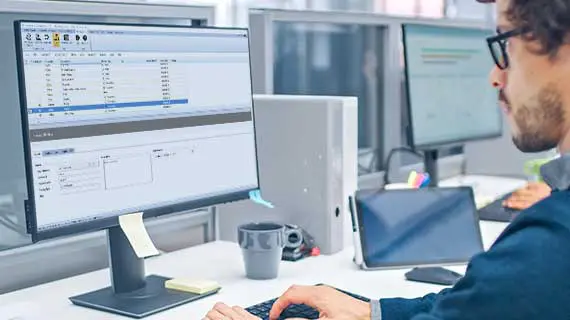

360 CORE is a simple, one-stop integrated tool for producing standardized, consistent PFMEAs.

- Determine the operation’s related procedure for every manufacturing operation.

- Use a single click to synchronize the manufacturing processes with the Process Flow Diagram (PFD).

- With just one click, synchronize the PFD and the PFMEA.

Watch the High QA Spotlight Webinar about PFMEA

Ready to see how it works?

Modernize Your PFMEA Process

Never Copy and Paste Again in Excel

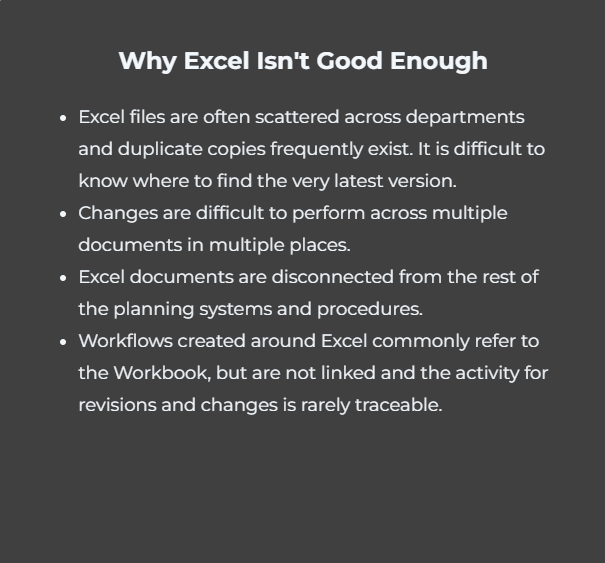

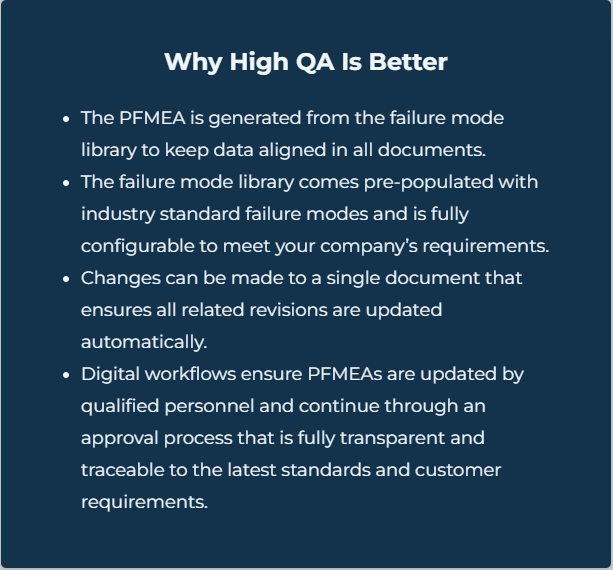

For a long time, the only option for a PFMEA was to use an Excel-based approach.

Now there is a better solution. Its time to modernize your PFMEA process.

Learn how you can replace Excel with High QA - Request a Demo

The C's of Powerful PFMEA

A crucial step in the continuous improvement process, 360 CORE centralizes all the data required to manage industrial production risks. All of the different PFMEA steps—from ballooning and part planning to inspection data collecting, FAI, PPAP, and reporting—share coherent information.

Hover over each word to learn more.

Control

Control

Continuous Improvement

Continuous Improvement

Collaborate

Collaborate

Comply

Comply

Centralized

Centralized

Comprehensive

Comprehensive

Consistent

Consistent

Cut-Down

Cut-Down

Clarity

Clarity

Complete

Complete

Learn how you can incorporate these powerful C's into your PFMEA.

With High QA software, we have been able to improve our manufacturing procedures. We have an average savings of 72% on quality planning and reporting processes.

Amr Sufian, Project Engineer, Beverston Engineering

Request a no obligation demo now

to see how High QA software can you save time and money.

Learn More about PFMEA

Manufacturers must identify process risks as soon as feasible, regardless of size or sector. Identifying necessary failure modes, developing risk mitigation strategies, and reducing the impact of failure modes on output are all made simpler by proactive diligence.

What is a PFMEA?

A Process Failure Mode Effects Analysis (PFMEA) is a structured analytical tool used by an organization, business unit or cross-functional team to identify and evaluate the potential failures of a process.

PFMEA helps to establish the impact of the failure and identify and prioritize the action items with the goal of alleviating risk. It is a living document that should be initiated prior to process of production and maintained through the lifecycle of the product.

When Should You Perform PFMEA?

A risk assessment tool for analyzing possible failures is PFMEA. It is most frequently applied when there is a worry about operational procedures that may damage products.

- New Process Introduction: Perform PFMEA when introducing new procedures to departmental teams. Ideally, leadership uses the analysis before implementing new processes to identify proper equipment care, tools, and production needs.

- Process Adaptation: Engage PFMEA when modifying existing processes. Any changes to production methods, types of machinery, and transportation can negatively impact multiple factors that cause chain reactions.

- Quality Risk Assessment: If you suspect a scenario in which quality is or could be compromised, use PFMEA to help create corrective actions. Process failures can result in defective products and customer returns that, in turn, decrease bottom lines.

- Business Relocation: Has your facility recently moved to a new location? If so, it’s an ideal time to conduct a failure analysis to assess potential production risks in the new environment. Taking such precautions is essential regardless of whether current process controls remain the same.

Experience the High QA Difference

OUR SOFTWARE

In order to plan, manage, document, and control manufacturing quality from conception and planning to production, reporting, and submittal, high QA software brings together engineering, production, and inspection teams both inside and throughout the supply chain.

OUR SOFTWARE

We have people with heart, tenacity, and a wealth of knowledge in addition to brainpower when it comes to producing high-quality software. Quality is what we breathe and live. Both our people and our software contain it. We may be considered the experts on quality.

OUR SOFTWARE

We can digitally revolutionize your manufacturing quality procedures if we work together. And that results in higher-quality products, happier customers, and a profitable business.

High QA is Your All-in-One, Get-It-Done Software for Manufacturing Quality

Reduce costs, improve quality, streamline processes, and maintain compliance internally and across your entire supply chain

Ballooning / Bubbling

One-Click to Balloon Drawings and 3D Models, Extract GD&T and PMI Data and Create Inspection Plans

First Article Inspection (FAI)

Powerful FAI Generation, Management and Reporting for Quality and Manufacturing

PPAP Requirements

The Most Complete Non-Excel-Based Manufacturing Quality Project Management Software Solution