First Article Inspection (FAI) Streamline, automate and mistake-proof your first article inspection process

Proving manufacturing compliance through an AS9102 First Article Inspection Report (FAIR) is essential—but it’s often a tedious, time-consuming process. Quality teams can spend over 24 hours juggling massive spreadsheets, complicated forms, and detailed documentation. Worse, last-minute process changes can lead to costly delays.

360 CORE transforms the way companies handle FAIRs. By automating and organizing every step of the AS9102 process, it slashes preparation time, eliminates errors, and keeps production moving on schedule. The result? Faster compliance, lower costs, and a smarter path to delivery.

“

High QA has been a game changer for us.

We have moved from completing 5-10 FAI reports a month to 5-10 a day.

Paul Nelson, Engineering and Quality Manager, Louis Industries

See how High QA can help you get more FAI reports completed in less time.

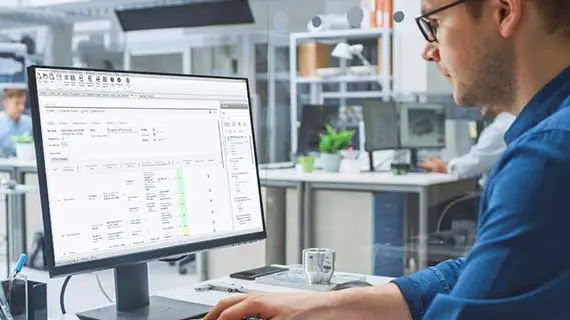

Powerful FAI Management for All Quality and Manufacturing Needs

- Out-of-the-Box Standard Forms

- Synchronized Inspection Results Data

- Paperless Environment

- Electronic Reviews and Approvals

- Centralized Database

- One-Click Ballooning and GD&T Extraction

- Customizable Forms, Workflows and Documentation

“

I am winning more aerospace contracts because I can get my FAIR’s out faster and cleaner than my competition.

Paul Nelson, Engineering and Quality Manager, Louis Industries

See how High QA can help you make better FAI reports faster.

Speed-Up Your First Article Inspection Process

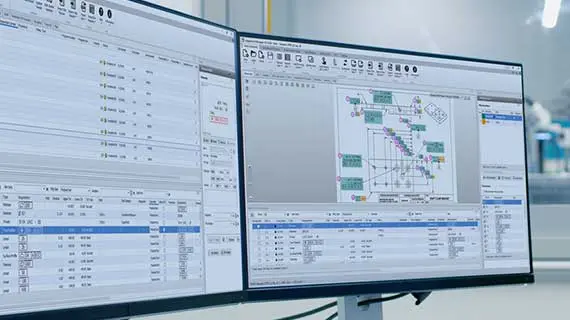

Automated One-Click Ballooning and GD&T Data Extraction

One-click is all it takes to balloon drawings and extract GD&T/PMI data using sophisticated OCR technology. A complete dynamic bill of characteristics and inspection plan is generated and linked to the ballooned drawing.

Quickly Import Measurement Results

Automatically import inspection results from any measurement machine or device. Manually input data or use sophisticated data collection apps to quickly record data.

Paperless FAI Submissions

Automatically combine all dimensional reports, certifications, ballooned drawings and other requirements into one complete multi-page PDF and deliver it electronically to customers.

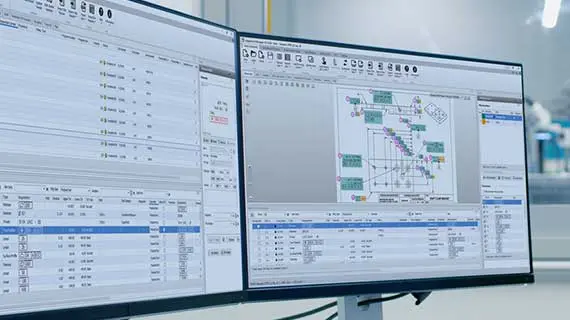

Powerful FAI Data Management

FAI data is stored in a centralized database. It is easily retrieved at any time for your team, customer, suppliers or regulatory audits.

The High QA Difference

It is time for you to become more efficient and make fewer mistakes. High QA streamlines your manufacturing process by organizing and automating every part of a first article inspection report, saving money and time while preventing errors along the way. And that results in higher-quality products, happier customers, and a profitable business.

Eliminate Paper

Digital files kept in a centralized database eliminate the problem of missing papers, unreadable information, or erroneous and incomplete data. In addition to speeding up audits and simplifying compliance, the digital solution offers complete transparency regarding who made what changes, when, and why.

Reduce Mistakes

Time-consuming transcriptions, laborious cut-and-paste tasks across spreadsheets, and manual data entry can all be eliminated with high quality assurance. A consolidated database houses all quality documentation, forms, and inspection findings. Data is higher quality and has fewer errors when less human input is used.

Increase Efficiency

You may achieve customer requirements and specifications the first time without having to redo any of your processes by using High QA’s initial article inspection method. Your processes and personnel will perform better overall if you manage every facet of the FAI, from data collecting and ballooning to analysis and reporting.