CMM

Gage

Data Collection

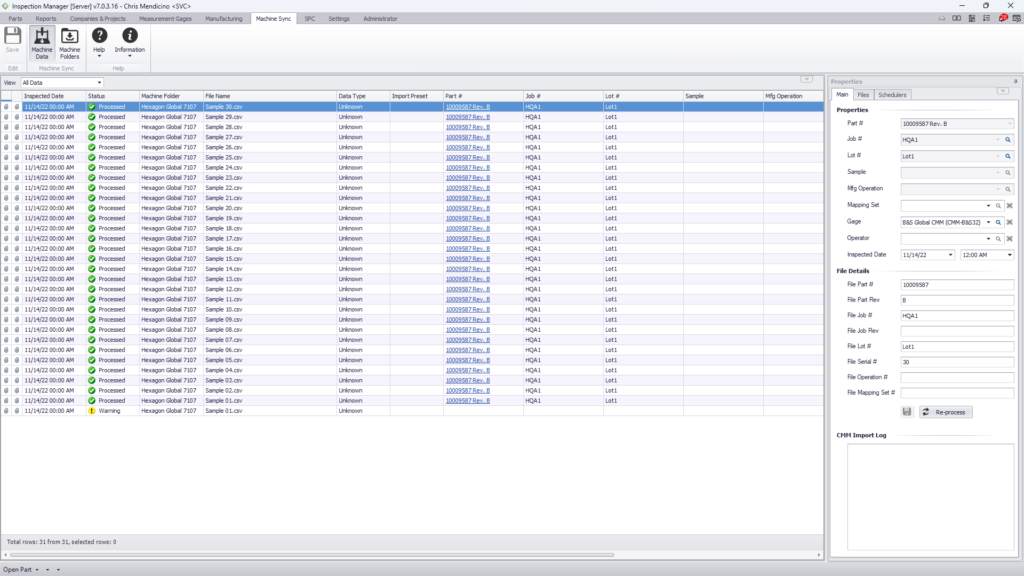

You can easily include automated inspection findings into your quality management workflows using High QA’s CMM & Vision Data Collection function. This solution guarantees accuracy, consistency, and efficiency throughout the inspection process by immediately gathering data from vision systems, Coordinate Measuring Machines (CMMs), and other comparable devices.

Overview

CMMs, vision systems, lasers, and machine probes are examples of automated inspection tools that generate thorough result files for accurate dimensional feature examination. By directly integrating with these devices, HighQA enables you to manage and record inspection results without the need for manual data entry. By automatically importing data files, AMDI (Automatic Machine Data Import) can further optimize workflows for users with compatible equipment.

Key Benefits

Automated Data Import

- Streamlines inspection results collection from CMMs, vision systems, and other automated equipment.

Error-Free Workflows

- Eliminates manual entry errors, helping to ensure consistent and accurate results.

Seamless Integration

- Connects directly with the Bill of Characteristics (BoC) and other tools within Inspection Manager.

Flexible Support

- Compatible with leading CMM software, including GEOPAK, PC-DMIS, MCOSMOS, and ZEISS CALYPSO.

Efficiency Without Extra Steps

With High QA, importing data from automated inspection equipment is simple:

- Connect your CMM or vision system to High QA’s IM/ 360 CORE.

- Execute inspection programs to generate results files.

- Optionally use AMDI for supported equipment to automatically import results into the BoC

CMM

Gage

Data Collection

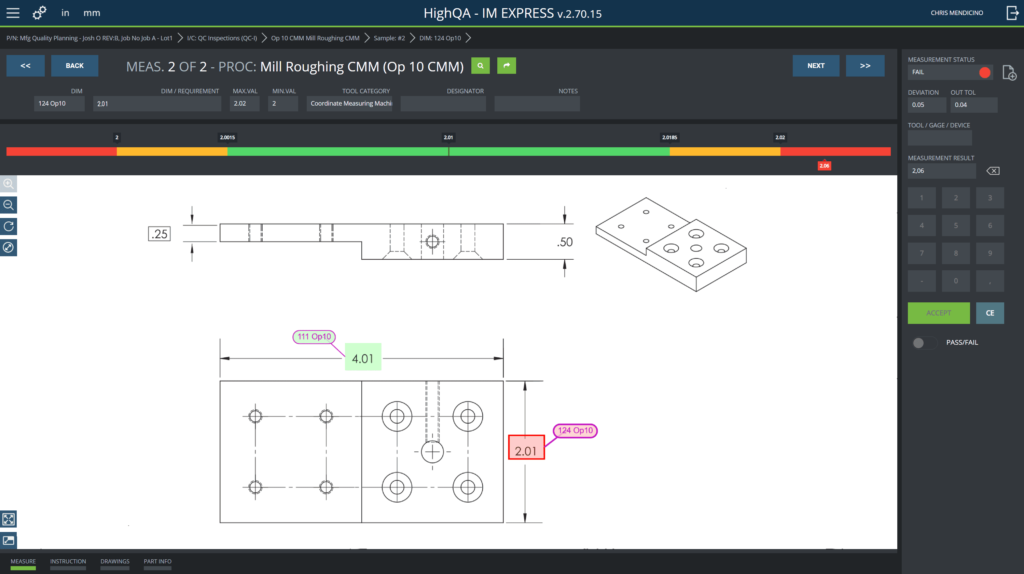

The Digital Gage Data Collection function from High QA allows for effective data collection from a variety of digital gauges, bridging the gap between automated and human inspections. With its smooth integration into your quality procedures, this tool guarantees precise, reliable, and traceable measurements.

Overview

Individual measurements must frequently be manually recorded during manual inspections, which are carried out using instruments like calipers, micrometers, and other digital gauges. By enabling the direct digital transmission of measurement data to the Inspection Manager, High QA’s Digital Gage Data Collection removes this inefficiency. AMDI can also be used with suitable devices to automate the import of structured data files for more complex configurations.

Key Benefits

Direct Data Transmission

- Capture measurements with the single press of a button using USB, Bluetooth, or serial connections.

Reduced Errors

- Avoid transcription mistakes by directly transmitting data into the BoC.

Broad Compatibility

- Supports leading gage systems, including Mitutoyo, Starrett, and Mahr devices.

Integrated Reporting

- Automatically populate inspection plans and reports with collected data.

Simplify the Process

With High QA, importing data from automated inspection equipment is simple:

- Connect your digital gage via USB, Bluetooth, or serial port.

- Configure the gage using High QA’s simple setup tools..

- For supported devices, use AMDI to automate data imports directly into the BoC.

CMM

Gage

Data Collection

The Digital Gage Data Collection function from High QA allows for effective data collection from a variety of digital gauges, bridging the gap between automated and human inspections. With its smooth integration into your quality procedures, this tool guarantees precise, reliable, and traceable measurements.

Overview

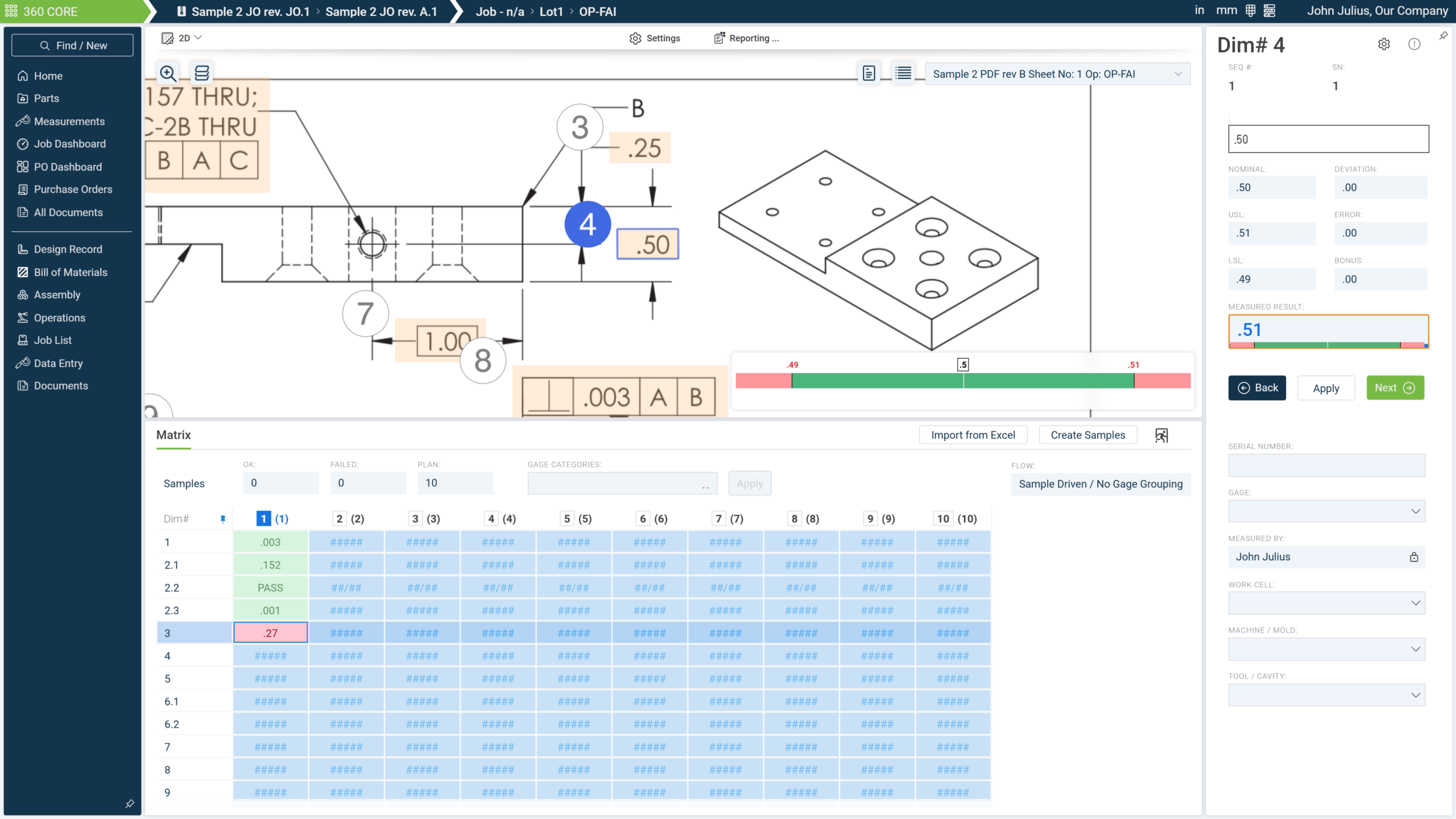

The findings of an inspection might come from a variety of sources, including manual measurements made with digital gauges or automated CMM programs. These procedures are unified by High QA’s Data Collection tool, which offers a centralized location for organizing and evaluating inspection data. Users may import, review, and edit results throughout various workflows with ease using tools like the Results Editor and IM Explorer.

Key Benefits

Flexible Collection Methods

- Import data from CMMs, digital gages, and manual entry systems.

Centralized Data Management

- Ensure all inspection data is accessible in one platform.

Advanced Navigation

- Supports leading gage systems, including Mitutoyo, Starrett, and Mahr devices.

Enhanced Reporting

- Automatically generate reports that reflect real-time results from all data sources.

Take the Complexity Out of Quality

High QA’s data collection tools are designed to adapt to your needs:

- Import results directly from automated equipment or digital gages.

- Utilize AMDI only for compatible devices to streamline workflows.

- Use the Results Editor to manually input or correct data.

- Access inspection records through IM/ 360 CORE, enabling efficient review and analysis.