How Do You Balloon Drawings and Extract GD&T/PMI Data?

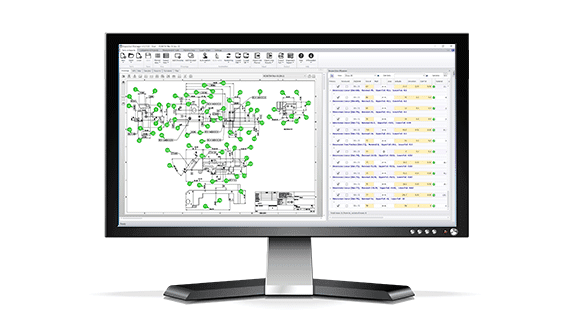

A crucial component of the quality management procedure is the ballooning software from High QA. You may save time and money by eliminating the need for manual ballooning and GD&T extraction with one-click auto-ballooning that uses optical character recognition (OCR). You can actually use balloon drawings for your quality process automatically.

See how ballooning and GD&T/PMI data extraction should be done.

Inspection Manager lets you balloon drawings and create bill of characteristics in minutes, not hours or days

> One-Click

Automatically balloon and extract GD&T/PMI data using sophisticated OCR technology

> No Cut and Paste

Prevents data entry and human interpretation errors

> One Consistent Data Source

Replaces multiple paper documents with digital files stored in a centralized database

> Manage All Drawings and Bill of Characteristics

Utilizes an all-in-one manufacturing quality management software

Watch the video to see 360 CORE in action.

Revolutionary Inspection Manager Features and Benefits

- One-click creates ballooned drawings and extracts GD&T from 2D drawings

- Automatic ballooning and extraction PMI data when opening a 3D MBD file

- Easily adjust balloon colors, shapes, and arrows

- Support for multi-page drawings

- Support for tabulated drawings

- One-click automatic conversion between metric/imperial units

- Revision controls automatically update balloons and GD&T data

- Accurate recognition of GD&T/PMI data with innovative Optical Character Recognition (OCR)

- Assign inspection tools, criticality designators and material specifications dynamically to the bill of characteristics

See how you can save hundreds of man-hours of time each year with auto-ballooning, importing CMM data and generating FAI reports in minutes.

Take advantage of 3D MBD in your manufacturing quality workflow

2D drawings have long been used by manufacturing quality engineers for planning and inspection. Many businesses increasingly demand that their suppliers employ a 3D Model-Based Definition (3D MBD) workflow as a result of the growth of Quality 4.0.

For this reason, integrating 3D models into your quality process is now easy thanks to High QA. When the 3D MBD file is loaded in the ballooning software, PMI data is automatically extracted and inflated.

- Automatically and intelligently extract GD&T and PMI from 3D MBD models

- Easily modify and manage extracted GD&T and PMI data

- Use 3D MBD data throughout your manufacturing quality process

Learn more about using 3D MBD in your manufacturing quality process.

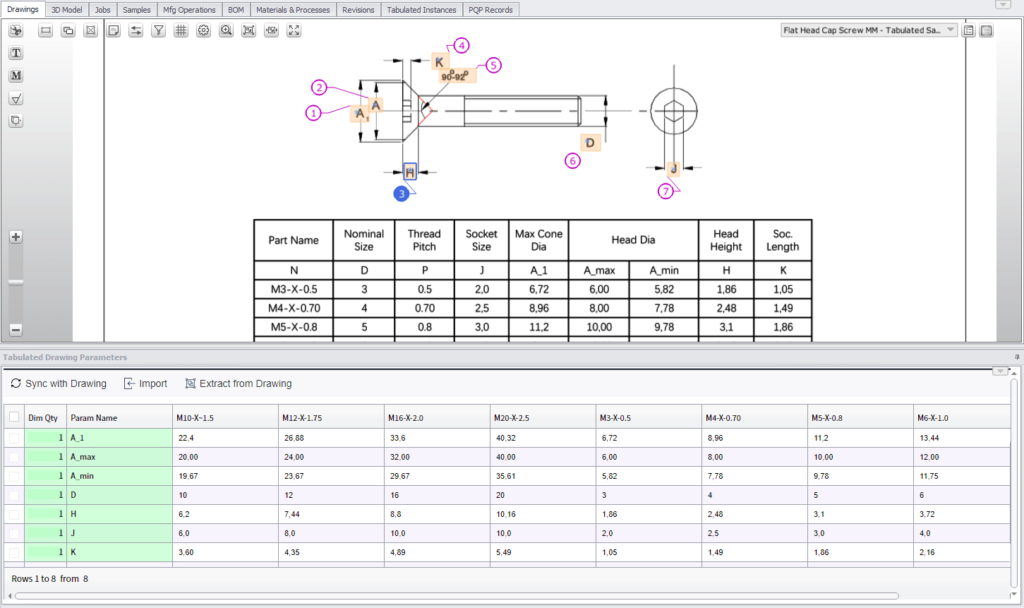

Speed Up Ballooning of Tabulated Drawings with Inspection Manager

It is not necessary to manually draft inspection plans for each instance of a part in a parametric or tabular drawing.

With Inspection Manager, you can automatically extract tabulated parameter tables from the drawing, specify tabulated dimensions, and build a tabulated master part record.

The ballooning program will then create part records for any or all tabulated instances with detailed inspection plans for every part with a single click.