The Quality Industry is Evolving. And that is Good.

Inspection Planning is Greatly Enhanced with 3D MBD

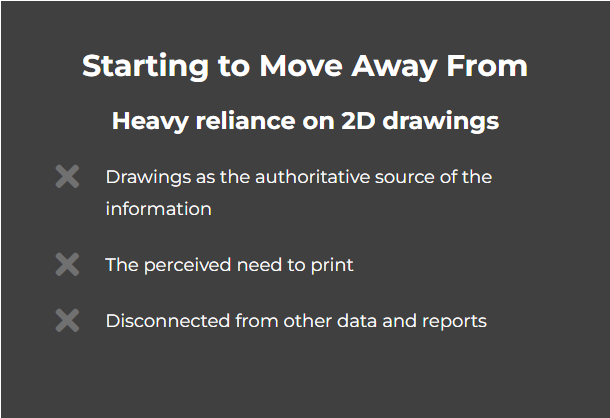

Solid and surface modeling approaches have gained popularity among design and industrial firms in recent years. However, the GD&T (geometric dimensioning and tolerancing) information required by the quality assurance organization is frequently absent from 3D models.

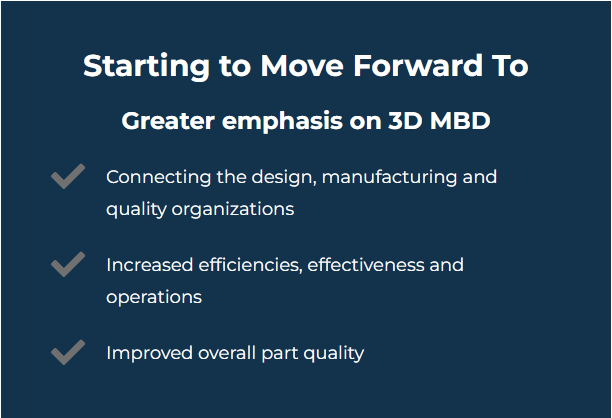

The primary issue with the standard CAD model is that in order to construct an inspection plan, it needs a separate drawing sheet to identify the datum structure, important features, and tolerancing. A 2D sketch is no longer necessary with 3D MBD since all relevant product information and inspection planning data are contained in a single model.

Similar to using a 2D design, 360 CORE allows you to include 3D MBD files straight into an automated, efficient manufacturing quality process.

High QA 3D MBD

Enhance Your Manufacturing Quality Process

with 3D MBD

See how you can incorporate 3D models into your quality process.

Easily integrate 3D MBD into your manufacturing quality workflow

Manufacturing quality engineers have long used 2D drawings for planning and inspection. With the rise of Quality 4.0, many companies are requiring their suppliers to use a 3D Model-Based Definition (3D MBD) methodology. Because of this, High QA has made it simple to incorporate 3D models into your quality process.

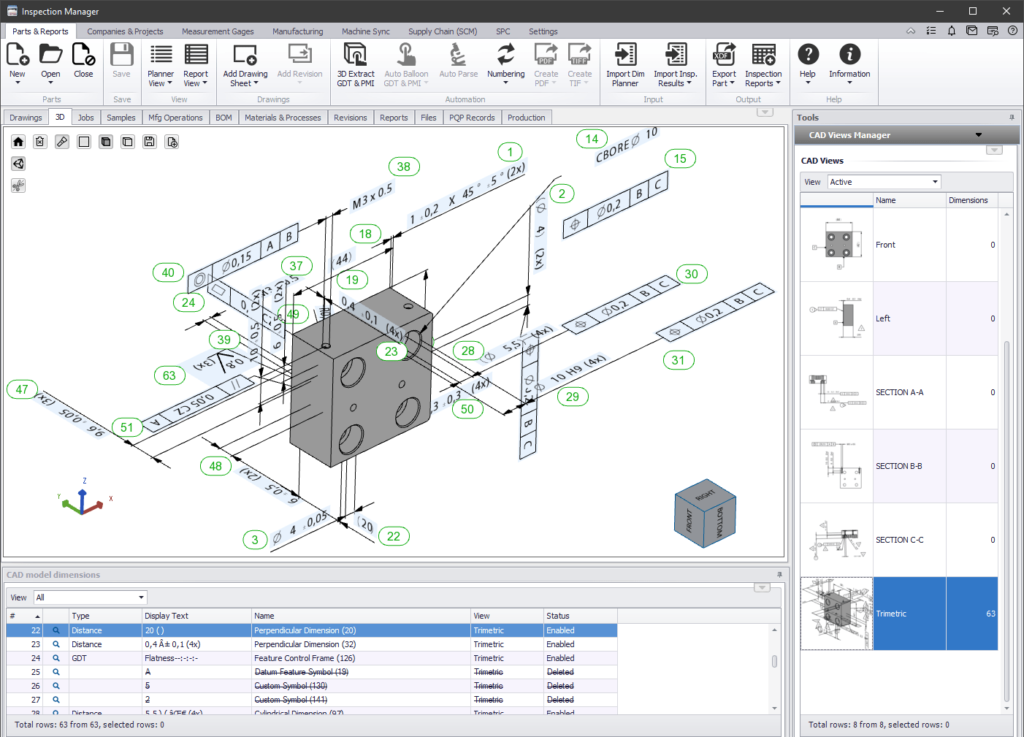

Intelligently extract, modify, and manage GD&T and PMI from native 3D MBD models

Gain understanding and clarity of 3D model PMI and annotated data

Streamline and automate the quality process from ballooning and planning to data collecting and reporting

Expand Your Capabilities by Including 3D MBD in Your Quality Process

- Supports Catia, Creo, NX, SOLIDWORKS, Autodesk and other CAD formats.

- PMI data is automatically extracted and ballooned when the 3D MBD file is opened

- Use 3D model directly in other 360 CORE processes

- View and use CAD data without additional CAD seats or licenses

- Create new dimensions or use drag-and-drop technology to relocate PMI data into essential views

- Rapidly create inspection plans from 3D models with PMI

- GD&T and PMI data is intelligently displayed and processed

- Show, suppress, hide and move PMI annotation as needed

- Generate AS9102, NCR, FAI, PPAP and other inspection reports

- Convert 3D models to 3D PDFs for viewing or STEP files for use in other manufacturing processes

No 2D Drawing? No Problem.

The usage of 3D MBD in quality workflows is effective. 360 CORE manages all design, manufacturing, inspection, and quality data in one digital location, making it a “single source of truth” for part quality data from both 2D and 3D files. As a result, there are fewer mistakes and inaccuracies since inspection time is decreased and human interpretation is not required. Increased accountability, traceability, and repeatability in the quality process are made possible by having a single, reliable source of data.