Trusted Partner with Industry 4.0 Solutions

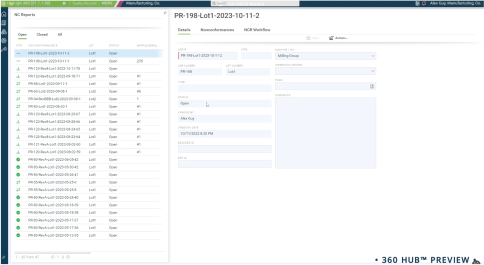

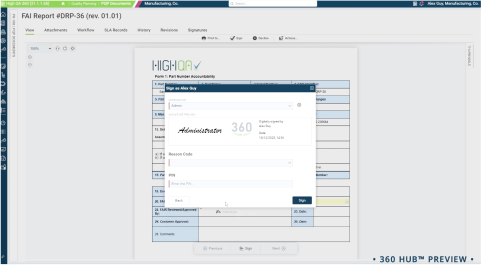

> Automate FAI/NCR processes with your suppliers

> Implement a quality-based digital thread

> Eliminate incoming inspections

Manage Supplier Quality More Efficiently

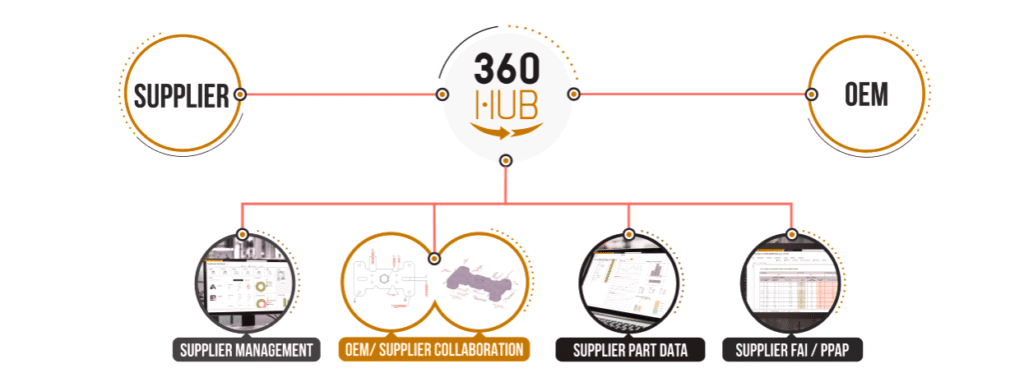

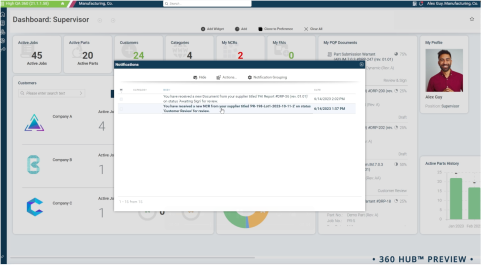

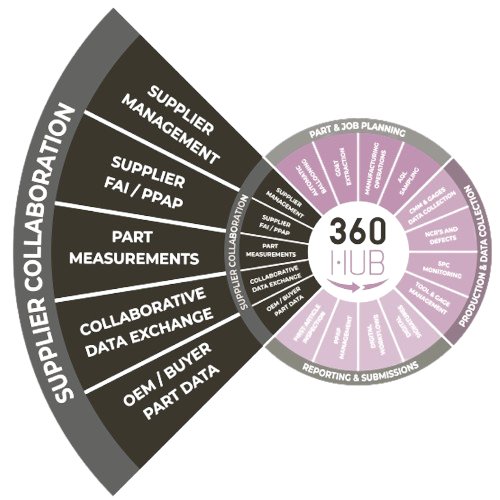

Collaborate with your suppliers by using a supplier quality management (SQM) software application that encourages consistency and reduces errors. 360 HUB ensures that everyone is working with the most recent information by facilitating real-time data sharing, which minimizes needless data entry, rework, and production delays.

360 HUB’s primary advantages include enhanced supplier management, secure cooperation, standardized documentation, accelerated First Article Inspection (FAI) and Production Part Approval Process (PPAP) paperwork, and smooth interaction with PLM and ERP goals and processes. Another benefit is a seamless data flow that includes RFQs, QA reports, prints, 3D models, and other important documents.

How it Works

All you need to do is invite your suppliers to the HUB to establish a safe and easy working environment. Throughout the production process, maintain alignment with your partners as if they were on the shop floor by sharing documents in a single, easily accessible area.

With 360 HUB, you and your suppliers will not just meet quality standards – you will exceed them!

Key Features & Benefits

Features

- OEM/Buyer Part Data

- Part Measurement

- Supplier FAI/PPAP

- Collaborative Data Exchange

- Supplier Management

Standardize

To make it easier to locate what you need when you need it, standardize the quality submission requirements for each provider and arrange quality papers in a consistent way.

Collaborate

Remove paper trails, non-value-added work, errors, and delays by collaborating on automated connection between suppliers and buyers for data quoting and FAI/PPAP report submission.

Predict

To plan inspections and establish stability in your operations and delivery schedules, forecast and maintain production schedules for producing and receiving high-quality products.

Learn

Because successful supply chain partnerships involve much more than just cost per part, learn qualitative information about suppliers and compare and evaluate quality data across various vendors to assess reliability and quality consistency.

How HUB 360 Works

- Suppliers are invited to the 360 HUB by buyers.

- Prints, models, and forms may be securely shared and exchanged via 360

- 360 HUB makes it possible to leverage data over time to select the best supplier, forecast quality and delivery, and precisely answer RFQs.

- Throughout the supply chain, 360 HUB facilitates collaboration and productivity with reduced friction.

The 360 HUB Difference

The ability of 360 HUB to standardize quality submissions across the supply chain and get past the challenges that have historically defined supplier-customer interactions sets it apart from other quality-focused IT solutions.

360 HUB gives consumers access to advanced ballooning data, Part Production Approval Process (PPAP) information, and First Article Inspection (FAI), which enables virtual and thorough supply chain management. Because data indicates that delays, rework, and late shipments due to poor quality can add considerable costs to the supply chain, HUB is a useful tool in today’s manufacturing environment. In addition to strengthening ties between manufacturers and their clients, 360 HUB assists in lowering or eliminating such expenses.